The Large Cargo Door Overview

Sewing an aircraft together in “stretches”

What is the ATR Large Cargo Door?

Large Cargo Door (“LCD”):

Key attributes are:

- 2.94m x 1.8m (116″ x 71″) door is a 272% larger door opening compared to standard door of 1.27m x 1.53m (50″ x 60″) door;

- 110°door opening with a 1.05m sill height (41″);

- Hydraulically actuated door (extremely reliable, with no in service issues since the very first aircraft converted);

- 9g forward net cargo barrier: cargo hold safety system;

- Integrated auxiliary door to allow crew access on loaded aircraft;

FR14 Fwd of LCD

FR13 Start of reinforced “doubler” area

FR20 Rear of LCD

FR23 End of reinforced “doubler” area

With an LCD conversion:

- the standard ATR front cargo door is removed;

- significant portions of frames 14 to 20 are removed;

- surrounding area of these frames are significantly reinforced;

- allows the installation of the new much larger Large Cargo Door (“LCD”);

- wide cross section of the tube conversion together with the new LCD – makes the ATR 72 the premier feeder aircraft for freight operators;

- integrated solution in the 5 – 9 tons market;

- complements larger B 737 / A 321 cargo aircraft operations;

- The new LCD door is operated by an integrated hydraulic system;

- The new LCD door allows you loading of large, oversized single piece cargo often carried by Oil Gas, Mining and Automotive industries.

LCD conversion generally selected when a fully “palletized” operation is needed;

STTB conversion selected if pallets or oversized cargo and containers are not required

(one can see the clear advantage and difference in the LCD compared to the original OEM door to the right [showing an approximation of the new LCD])

Large Cargo Door (“LCD”)

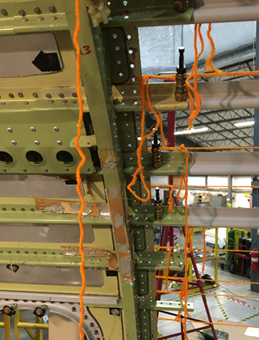

During the installation process

- significant strengthening and doublers installed on the surrounding area

- wraps around the airframe to ensure no compromise in the integrity of the aircraft

- offers strong anchors for the Forward 9 G net

- interior passenger configuration, secondary structure, related equipment stripped out

- all linings, seat track, overhead bins, air distribution ducting, lavatories, defunct wiring/looms, forward cargo compartment and gallies all removed

- replaced with IPRC’s own new strengthened secondary structure

- at the end of the conversion makes the cargo aircraft is lighter than the pax aircraft

- additional modifications include installation of seven 7 electrical smoke detectors, LED tube lighting

- floor reinforcements to 400kg/m² (82lbs/ft²)

- The Cargo Configuration matches the requirement EASA CS 25.857 Class E

A complicated “Lego” set installed:

- over 30 000 parts making up the LCD conversion

- over 1 000 individual unique structural PNs

Green metal work is the reinforced “doubler” area

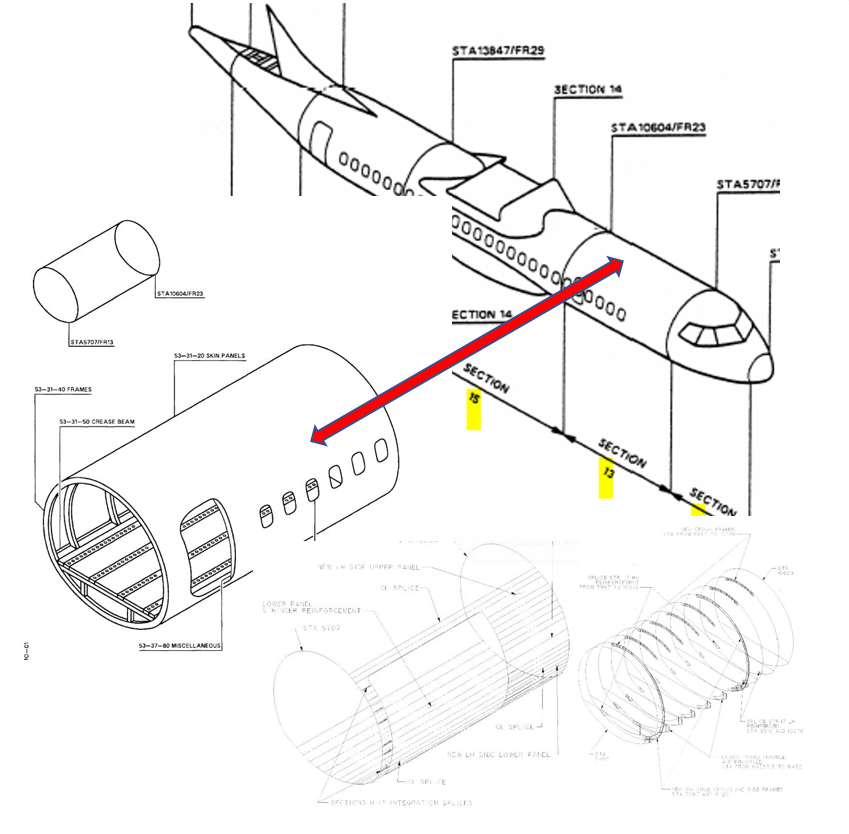

Section 13

The primary area the Large Cargo Door is fitted in

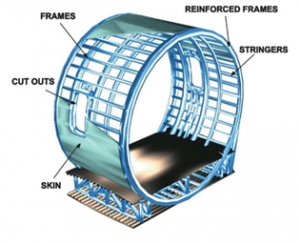

The ATR fuselage is built from ‘stretches’ – five (5) key sections;

The primary section the LCD affects is the “Section 13” as shown below.

During the conversion process, we replace ± 40% of the original “skins” in Section 13 and we also replace and reinforce ± 60% of the frames in Section 13.

Section 13

Section 15

9G Loading safety and Cabin Modifications

- the Forward Net has a “9G’’ regulatory requirement to ensure safety in the cockpit;

- sole aim of stopping the full load in the event of a crash.

- The space between the net and the cockpit serves for the extension of the net, in case of an accident as the load cannot be absorbed directly by the cockpit structure.

- The net works on a hook system, folds with sewing threads made to break and thus absorb the load gradually.

- The net completely extended and along the cockpit door prevents it from opening.

- The crew door a small door within the LCD – is not an emergency exit. The emergency exit from the aircraft (after modification) is the cockpit hatch door.

- To aid operational efficiencies and ease of access and loading, the Forward Net (weighing only 15kgs) is seperateable into 2 parts;

- attaches to each other through easy access and connections devices – fully installed in approximately 3 minutes by a single person;

9g Forward Net hooks – no cargo loaded beyond the roller ball mat with CLS